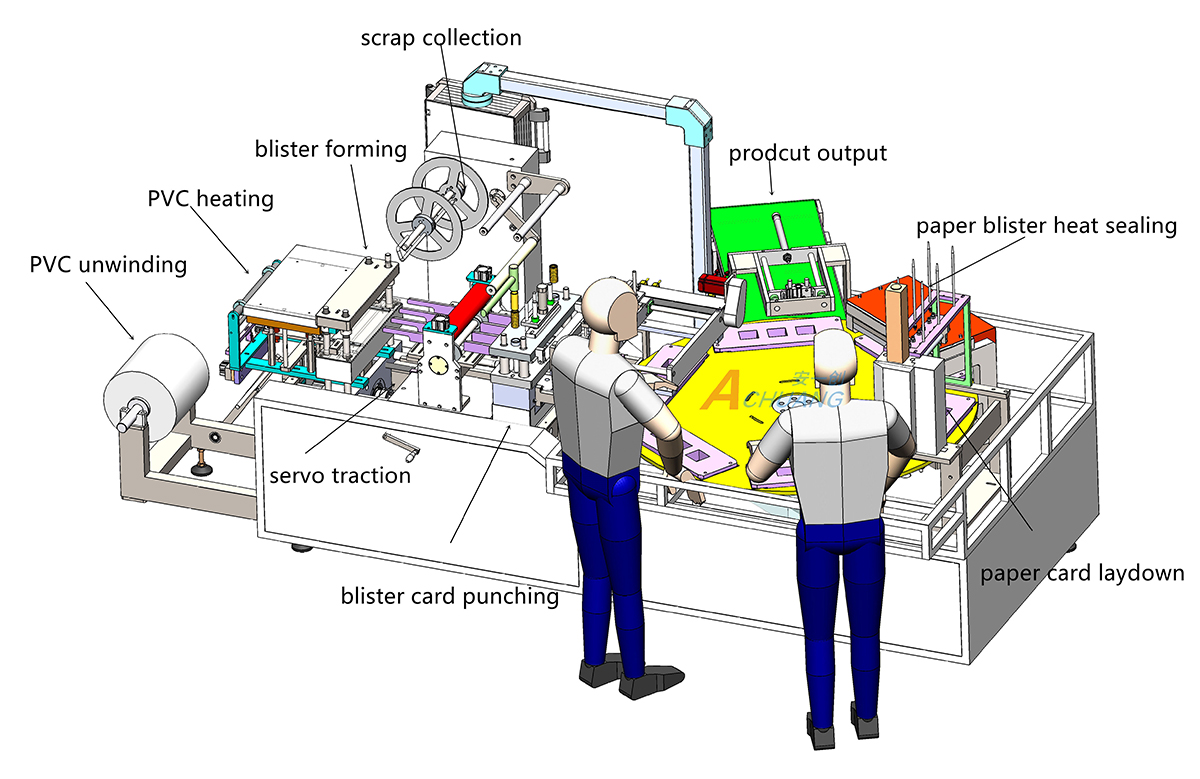

AC-380 Automatic Blister Paper Card Packing Machine

Usage

AC-350 is Suitable for half-cover seal blister card packaging, such as daily commodity , small hardware (battery, electronics, glue), stationery, auto part (brake pads, spark plugs), cosmetics (lipsticks),toys (small cars), food etc.

Function

--Automatic forming blister, punching the blister, scrap collect,dropping paper card, paper blister heat sealing, product output automatically.

--Accurate temperature control module, PVC shortage alarm, insufficient air pressure auto stop and automatic warning for damaged electrical parts.

--Human-machine interface and PLC control system, and is equipped with counting, starting password, fault reminder, maintenance reminder and other functions.

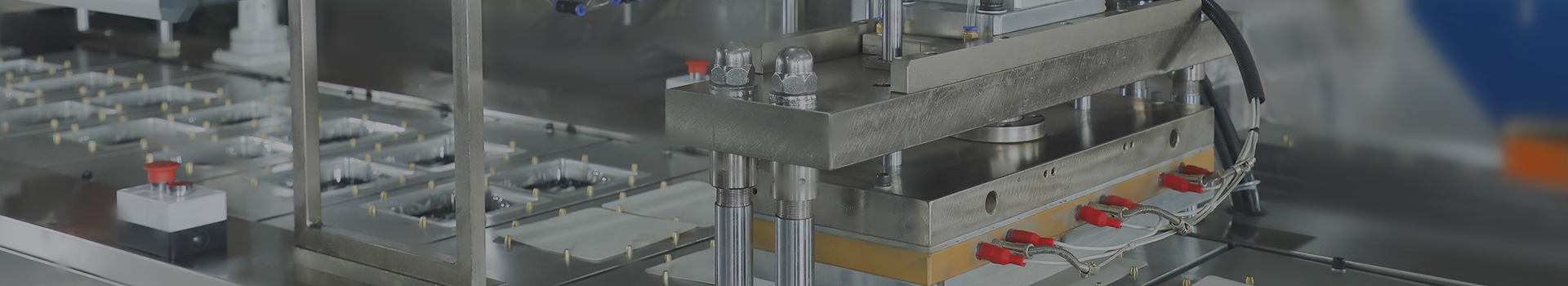

Machine detail

Flow Diagram

Working procedure:

PVC loading→PVC heating→blister forming→servo traction→blister cutting→PVC scrap collection→blister transfer to the turntable→worker place product→paper card lay down →hot sealing→product output

(optional choice:labelling machine, ink-jet printer)

Main parameter

| Production speed | 15-20 times/min |

| Stroke range | 30mm-200mm |

| Max forming area | 370mm*180mm |

| Max standard forming depth | 50mm |

| Forming heating power | 3kw(*2) |

| Heat sealing power | 4kw |

| Total power | 13kw |

| Air consumption(air compressor) | consumption ≥0.5 m³/min |

| Air Pressure | 0.5-0.8mpa |

| Mold cooling water (chiller) | 50 L/h |

| Packing material(PVC)(PET) | thickness0.15mm-0.5mm内 |

| Packing material (cardboard) | 200g-500g |

| Max paper dimension | 400mm*200mm*0.5mm |

| Total Weight | 2300kg |

| Machine dimension(L*W*H) | 4485mm*1550mm*1800mm |